How We Make Molds for Textured Glass Countertops, Bar Tops & Table Tops

Introduction

The texture of our glass countertops is determined before the glass ever enters the kiln — it begins with the mold. This guide explains the six mold materials used in professional kiln-formed textured glass countertops fabrication, and how each one shapes cost, durability, detail clarity, and the final character of your surface.

Why Mold Selection Is the Foundation for Textured Glass Countertops

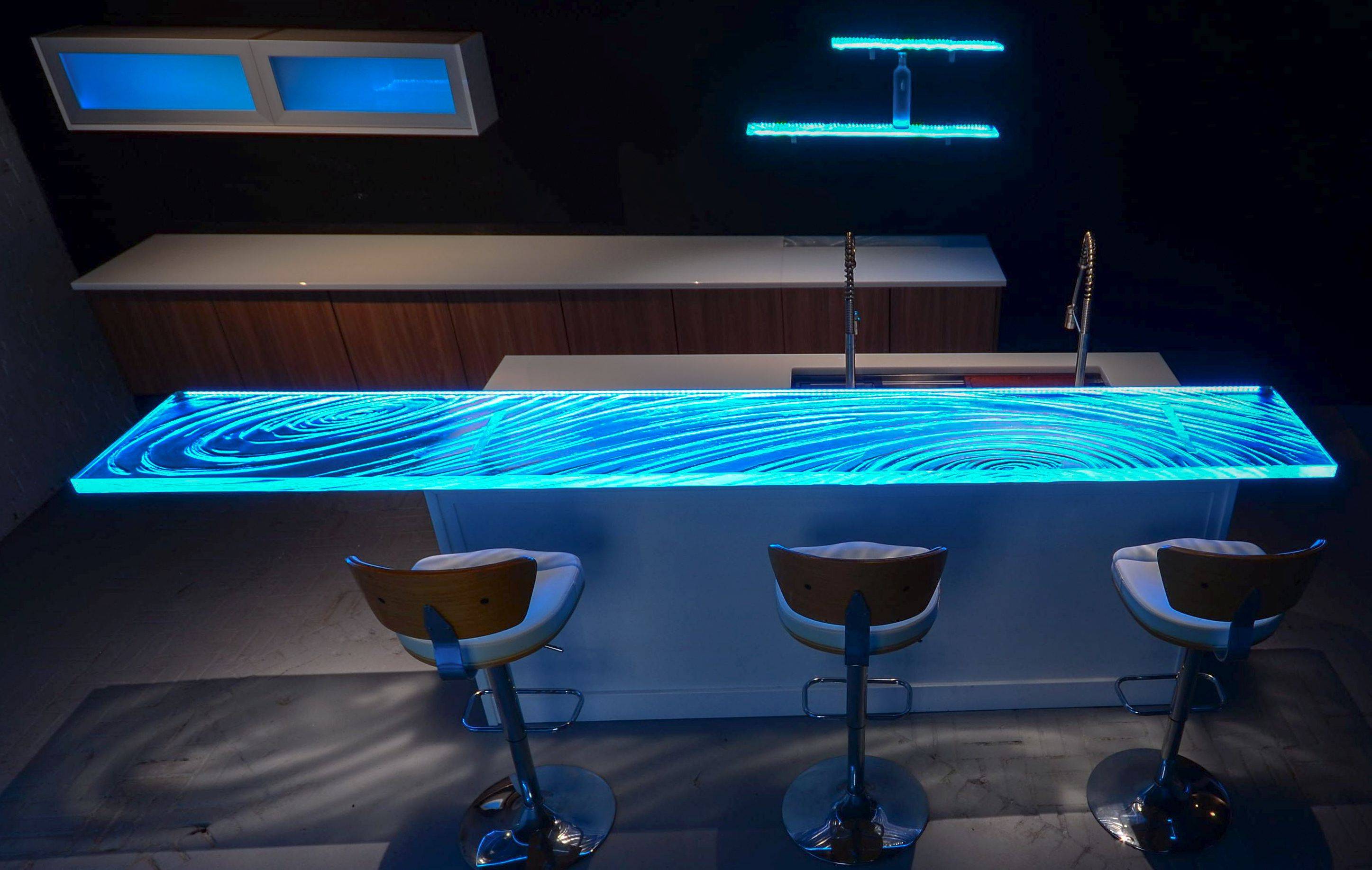

When a client commissions a custom glass countertop, bar top, or architectural glass element, the visible result — the depth of texture, the way light moves across the surface, the crispness of every edge — is inseparably tied to a decision made before fabrication begins: which mold material to use.

At Downing Designs, mold engineering is not an afterthought. It is the first conversation we have about any textured glass project. The right mold material directly determines:

- Surface texture sharpness — from organic and flowing to razor-crisp geometric detail

- Glass release behavior — how cleanly the glass separates after firing without surface damage

- Thermal stability — how the mold holds its shape through kiln temperatures reaching over 1400°F

- Repeatability — whether a design can be replicated identically across multiple pieces

- Production economics — single-use versus multi-use molds and their cost implications

For high-end residential kitchens, restaurant bar tops, hospitality installations, and architectural commissions, all five of these factors matter simultaneously. Below, we break down each mold material we use, explain the trade-offs honestly, and describe exactly which applications each one serves best.

The Six Mold Materials Used in Textured Glass Countertops Fabrication

Mold Type 01

Mold Mix 6 — Refractory Casting Material

Mold Mix 6 is a specialty refractory casting compound engineered for kiln-formed glass work. It has embedded fibers which knit the ceramic together, and handles thermal cycling reliably, holds fine detail well, and can be reused across multiple firings when handled with care. A kiln wash or release agent may not need to be applied before each use to ensure clean glass separation.

Mold Type 02

Bisque Fired Molds — Pre-Fired Ceramic Molds

Bisque fired molds are fired once to above 1900°F before glass casting begins, a step that strengthens the internal structure and stabilizes the surface at a molecular level. This pre-firing process eliminates the moisture-related cracking risks common in unfired molds and creates a surface that accepts refractory coatings uniformly. The result is a mold capable of surviving the most demanding thermal environments. Bisque mold usually require kiln wash to separate the glass from mold.

Mold Type 03

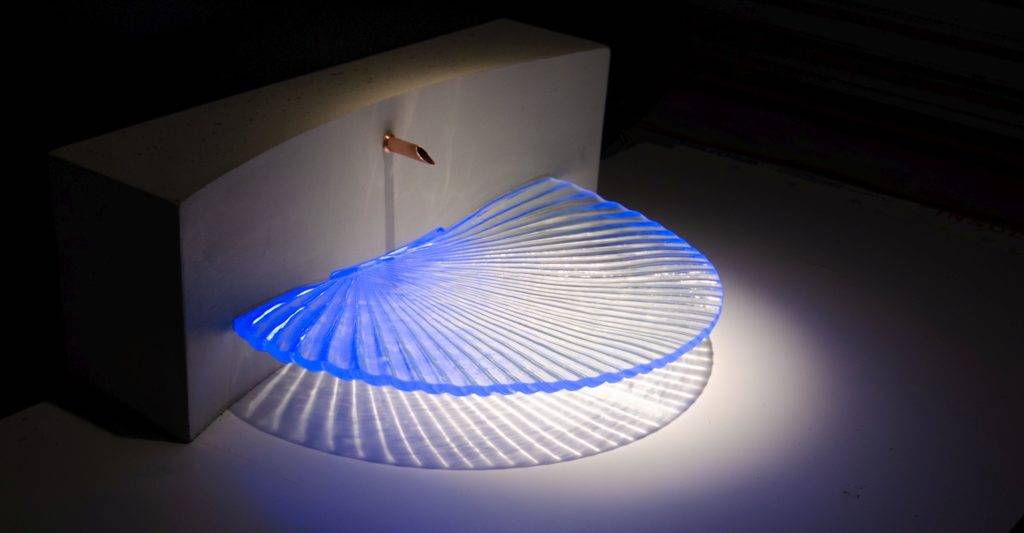

Sand Bed Molds — Traditional Organic Impression Casting

One of the oldest and most intuitive methods in glass casting: compacted sand is shaped, textured, or impressed to create the mold cavity (kiln-carving). Sand beds cost a few hundred dollars (inexpensive), easily modified, and produce surfaces with a natural, non-mechanical quality that cannot be replicated by machined or cast molds. They are typically single-use — the sand is disturbed during glass removal — but their aesthetic contribution can be irreplaceable.

Example of Artistic Glass Countertop created in a Sand Bed with Sand Dollar stamps.

Sand Dollar Edge in Glass Countertop

Mold Type 04

Plaster-Silica Molds — The Traditional Glass Casting Blend

The plaster-silica combination has been used in kiln glass for decades and remains a trusted workhorse material. Plaster provides workability and captures detail during the pour; silica flour improves thermal stability and reduces thermal shock cracking. The blend is mixed to a specific ratio depending on the size and complexity of the piece, then applied over a model or poured into a form. These molds are often one and done

Graphite Molds — Premium Performance for Critical Detail

Graphite is among the highest-performing mold materials in kiln glass fabrication. It is also used in metal mold making. Its natural thermal conductivity distributes heat evenly across the mold surface, reducing hot spots that can cause stress fractures in pieces. Its non-reactive surface chemistry means glass releases cleanly without heavy application of release agents, and its dimensional stability under extreme heat allows it to hold tolerances that no other material can match over repeated firings.

Mold Type 06

Fiber Blankets & Rigid Boards — Flexible Texture & Insulation

Ceramic fiber materials serve a dual role in our process: they function as thermal insulation during firing, and their surface texture imprints naturally onto soft glass. Rigid boards can be carved, cut, or layered to create texture at scale. Blanket materials, when crumpled or folded deliberately, produce impressionistic surfaces that feel handmade and unpredictable. Both are often used in combination with other mold materials in layered constructions.

Mold Material Comparison at a Glance

The table below summarizes performance across the four factors that matter most in professional glass countertop fabrication:

| Mold Type | Cost | Durability | Glass Release | Detail Sharpness |

|---|---|---|---|---|

| Mold Mix 6 | Medium | Good | Excellent | High |

| Bisque Fired | Higher | Excellent | Excellent | High |

| Sand Bed | Low | Single-use | Good | Medium (organic) |

| Plaster-Silica | Low–Medium | Moderate | Easy | Good |

| Graphite | High | Excellent | Very Good | Outstanding |

| Fiber / Board | Medium | Moderate | Variable | Medium (organic) |

FAQS Frequently Asked Questions About Textured Glass Countertop Molds

What mold material is best for a big textured glass countertop?

For one-of residential countertops with organic textures, Downing Designs uses a sand bed and kiln-carves the molds. For precise geometric textures or commercial quantities, Mold Mix 6 or graphite molds deliver superior consistency and longevity. Bisque fired molds are ideal for architectural installations or plates where thermal stability is critical.

How many times can a glass casting mold be reused?

Reusability varies significantly by material. Graphite molds can withstand dozens to hundreds of firings with proper care. Bisque fired ceramic molds are also highly durable across 50+ production cycles. Mold Mix 6 offers 10-25+ firing reusability. Plaster-silica molds are more limited, typically lasting once. Sand bed mold textures are generally single-use by nature, but the material is 100% recyclable…ready to be levelled and carved into the next custom textured glass bar top.

What kiln temperature is used for textured glass countertops casting?

Kiln-formed glass fusing occurs in the range of 1,450°F to 1,500°F (760°C to 815°C), depending on the glass type, mold material, and desired surface character. Mold materials must be rated for and stable at these temperatures throughout the full firing and annealing (~1000°F) cycle.

Why does mold material affect the texture of glass countertops?

At kiln temperatures, glass becomes viscous and flows into and against the mold surface, capturing its texture, grain, and character in precise detail. A smooth, fine-grained graphite mold produces ultra-crisp edges. A textured sand bed produces organic, naturalistic impressions. The mold is not just a container — it is the tool that defines the surface aesthetics of the final piece. There is also a chemical interaction with hot glass that expose different interactions with each mold material.

The Downing Designs Approach: Mold Engineering Before Textured Glass Fabrication

Many glass fabrication shops cast glass. Downing Designs engineers the mold first — because we understand that the most critical fabrication decision is made before the kiln ever turns on.

Our process begins with a detailed consultation that covers the design intent, the installation environment, the desired surface character, etc. From that information, we identify the appropriate mold material, construct or kiln-carve the mold, apply the correct release system, and verify final geometry before the first piece of glass is loaded.

This systematic approach allows us to produce custom textured glass countertops and bar tops that perform beautifully over decades of use — in luxury residential kitchens, high-end restaurant environments, hospitality installations, and architectural applications where both visual quality and structural integrity are non-negotiable.

Start Your Textured Glass Consultation

Whether you’re planning a textured glass countertop, a bar top commission, or an architectural glass installation, we’d be glad to discuss mold options, texture possibilities, and fabrication timelines specific to your project.

Jeff Downing

Founder, Lead Designer & Custom Glass Countertop Expert

Jeff Downing of Downing Designs, is a Tampa, Florida–based design studio specializing in custom Glass Countertops, Glass Bar Tops, Glass Vanity tops and Glass Stair Treads. With decades of hands-on experience, Jeff is widely recognized for designing custom glass surfaces integrated with LED lighting to create dazzling statement pieces.

"Glass. Lights. Ambiance".