Last updated on January 4th, 2021 at 06:56 pm

Glass Countertop High Bar Support Options

Glass High Bars can be deployed in many areas, not just the kitchen above an Island base. Often, there is no base and we show our favorite style of Glass High Bar support. We find it best to deploy 4″ stainless steel tubing with 1/8″ wall thickness as the vertical posts. In this blog, we will show how 2 different approaches that solved the issue of how to secure the base and the glass high bar.

Glass High Bar Supported By Metal Brackets

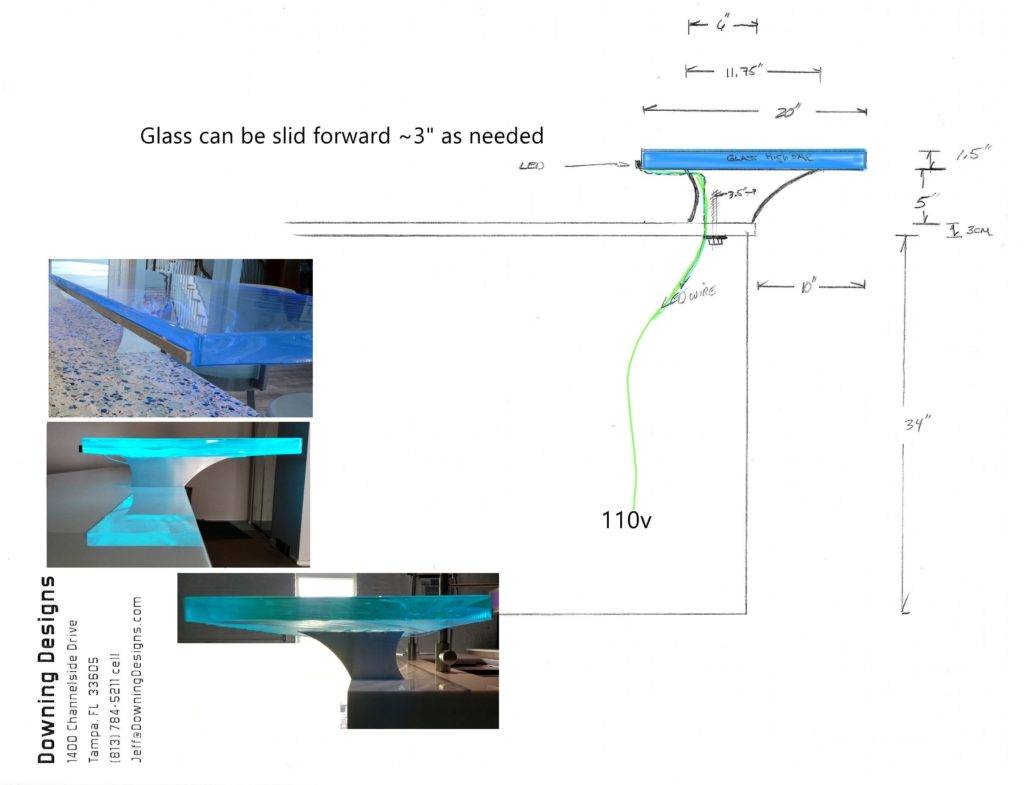

Often our Glass High Bars are to be floated above a ~36″ high lower countertop. Most High bars are targeted at 42″ AFF (Above Finished Floor). Since our Glass is 1.5″ thick, we fabricate our cantilevering glass high bar supports at 4.5″ tall (4.5 + 1.5 +36 =42). Many different widths are available for your Glass High Bar, but we recommend 20″ where possible. This allows for 10-11″ of overhang, and is plenty to accommodate plates, glass, etc. It also allows a bigger canvas for our textured glass countertop art to be designed upon. We have noted elsewhere that many Glass countertop high bars are installed in what we consider very old-fashioned ways, using multiple 1″ diameter metal supports and drilling through or gluing to the bottom of the glass. We find fault with this for textured glass for several reasons:

- When Glass Countertops are drilled, that is a perfect place for the genesis of cracks…especially if the glass is torqued. Cantilevering glass counters this way creates torque…especially if you slip/fall and grab the countertop.

- You cannot always get a deeply textured glass countertop to perfectly align on 4 or 6 vertical 1″ diameter metal posts. This is never a pretty solution either with all those posts. Remember, you will have to through drill your lower countertop to accomplish this, and you need to know what is under those points.

- Stylistically, using our custom cantilevering brackets simplifies the look greatly. From all angles the 2 supports we recommend promotes openness vs closed off knee walls or a gauntlet of stanchions.

- Our system is safer and much more robust, requires no drilling of the glass countertop and only 2 holes in the lower countertop. Clean, modern, and sleek looking for your kitchen island design. Our inspiration comes from the bow of luxury yachts, and racing cars.

Inspiration for Cantilevered High Bar Design

Dazzling Glass Countertop High bar at Downing Designs in Tampa,FL:

Glass Countertop High Bar Support drawing side view

Glass High Bar support with Stainless Steel Square Base.

We took a 16″ x 16″ x 3/8″ stainless steel plate, water-jetted a hole to allow for tight passage of the tube, protruded it by ~1/4″ and welded the base to the tube. This provides a very clean look from the top. 4 holes were drilled at the corners and the structure was attached to the concrete and tile floor with Red Head Drop In Anchors . Much of the tile directly under the tubing was removed to allow passage of the wiring without slicing it.

The LEDs and their feeder wire present another challenge. Since the wire to drive the LED strip lights are 1/4″ in diameter, we drilled a hole in the rear of the support, fed the wire down the stainless support tube, and out the bottom. The grout lines were a perfect conduit to the power supply and LED strip light controller. We aligned the bases to best advantage and then used our Dremel powered grout removal tool to take out all the grout, stuff the 1/4″ LED cable in the groove, and recovered with same color grout.

The Glass High Bar was secured to the 4″x 10″stainless post top with ultra-clear silicone, and allowed to set 24hrs before cured. This 24 hr set time is a consequence of the undulating textured glass bottom,mated with the flat stainless post top. Some of the gaps are 1/2″ and take time to cure vs smaller gaps.

Glass High Bar with Custom Stainless Steel bases supports

Glass High Bar support with Stainless Steel Posts cemented into the ground.

In this instance, we had new construction and access under the concrete slab to secure the stainless posts. Here we made the posts ~24″ too long to secure into the ground and fill with hydraulic cement. The concrete slab was cut into and drilled to provide access for the posts. The posts were also drilled so as to allow the concrete to flow freely inside them to fill the hole.

Rapid Set cement is amazing and can be set in 30 minutes, ready for action. We created a scaffold apparatus around the support. Made sure it was perfectly level, and poured. Using plumb lines assures that each post top is level with the next.

In this case the stainless post tops were pre-tapped to accept the Low Profile Caps used to secure the glass. Precision measurements are a must in aligning the posts. We use templates to ensure perfect fits.

No silicone is needed. We pre-drill the glass high bars to make these heavy glass counters secure from the eventual party that will be playing out upon them.

No LEDs striplights were used, but the conduct of the lighting feed would be hidden just as above.

Glass High Bar with Stainless Steel Post supports