Last updated on April 19th, 2022 at 07:36 am

2022 Price of Glass Countertops Compared.

For a customer looking to compare the price of Glass Countertops, White Glass (Nanoglass) countertops and Sea Glass countertops, for their modern kitchen or bath design, there is a dizzying array of countertop choices. Big box retailers offer many lesser quality countertop material selections, but sometimes it can lead to paralysis by analysis. I have been in your shoes shopping for custom countertops, and that was the initial impetus for starting Downing Designs countertop store in 1999. We knew someone needed to step in and clarify things in plain english for the high-end consumer.

Our Glass Design Center was created to show off kitchen and bath displays with countertop materials that are unequalled, and never seen in a retail outlet, except in design magazines. Long ago, we partnered with the top company in each product category, and sold their products. Soon afterwards, we knew the market needed a more unique and customizable product, so we developed our own glass countertops, glass sinks, and concrete countertops, and cut out the middlemen. Clients love touring our Tampa factory and design center and see our full-scale displays. They are fascinated by how our glass countertops are made. It’s a highly interactive process where they can direct the artistic output. No other countertop offers such direct input on its creation.

It is true that we offer the most expensive glass countertops you can find anywhere in the world, but that does not mean they are unaffordable. Our Glass Design Center displays clarify how a pairing one exceptional (high-value) design element with a simple and pure (lower-cost) material can create a dramatic kitchen or bath design. Downing Designs is not interested in the “usual suspects” that anyone can get at Home Depot, just the best custom glass countertops that require craftsmen to design, create and install with careful attention to detail.

Glass Countertops Buyer Guide:

Price of Glass Countertops

The average retail price of a 1.5″ Glass Countertop is between $250/psf and $700/psf.

How are Glass Countertops made?

Ultra Low Iron Float Glass is stacked and fired in kilns atop a textured sand bed to over 1400 degrees F. Then annealed over several days, cut, polished, accented with custom LED lights and installed.

What is the Largest Size of Glass countertop?.

Large glass countertops up to 130” in length x 59″ wide without a seam. Our Kilns are huge and can make very large pieces.

Typical Thickness of a Glass Countertop?

1.5” is the typical glass countertop thickness. 1.5” thick glass weighs ~21lbs per square foot. Thicker glass adds to cost exponentially as the glass annealing time is an exponential function of thickness. E.g. 1.5” thick glass countertop will require about 10 hours to properly anneal. For a 4” thick piece, it will take ~14 days. This exponentially higher time in the glass kiln translates into a higher cost glass countertop.

Compare Glass Countertops Design Options.

Textured glass countertop designs can take many shapes. We offer Artistic hand-texturing of our glass countertops to enhance the flow of the space where it resides. Hand-made textures designed to flow with your room are created interactively and requires experienced foresight to visualize how our textural flow can elongate your kitchen or bath. A well-designed custom glass countertop will have a large visual impact on the room it inhabits. Static texture options are available, but these do nothing to suggest integration with the overall room flow. Static and Flowing Hand-Textured glass countertops cost the same. For this reason, over 95% of our sales are Hand-Textured.

Glass Countertop Edge Polishing.

Polishing Glass to an optically pure quality takes 11 steps and a great amount of skill. CNC machines produce highly visible lines on the edge. “Liney but shiney” may be OK for granite, but it visibly obscures the refraction potential of the glass. Make sure you inspect the quality of your edge polish before buying glass counters. Roundovers on the top are preferred vs sharp 45 degree bevels. Bevels chip easily. Round overs do not.

Cutouts. Cutouts for holes for supports, sinks and faucets need to be done with a waterjet. Water jetting glass runs about $150 per hour for setup and cutting.

Back Painted Glass.

Textured Glass Countertops are transparent, and can be back painted any color to hide the contents of your cabinets below. Glass backsplashes can be fabricated that offer any color match from Benjamin Moore or Sherwin Williams. Back painting glass metallic silver adds great depth to the textures and is the #1 glass backsplash color. Non-Textured back painted glass is not a good candidate for LED lighting since it only illuminates the edges…not the interior.

Are Glass Countertops durable?

Yes. Glass countertops are very durable. as evidenced by the large volume of consumer and commercial repeat orders. Nobody buys a bad surface a 2nd time. Textured glass countertops edges are rounded over (in our shop) and dissipate the energy from collision with bottles, elbows, chairs etc,

Integral Glass Color. Color can be added between layers of glass countertops before firing using glass frits. This enhances the artistry of the design, and is permanently fused to the glass. Please choose your design carefully! There is no laser tattoo removal for fused glass countertops.

Lighting. LED’s and down lighting can add dimensional depth to textured glass countertops. LEDs can be installed at the rear edge of the countertop between the wall and countertop. For high bars, stainless steel covers can be added to finish the look. Down lighting with narrow beam LED’s highlights the textural shadows below the glass.

Brackets. Most high bars require metal support brackets and/or Low Profile Caps to secure the glass above the lower countertop or knee wall. Textured glass is tricky because it has an undulating bottom to be secured to a flat support. We recommend a custom support bracket that elegantly and securely cantilevers the glass over the lower countertop. Most overhangs we install are 10″ or so. This gives plenty of room for even tall people to stretch their legs in their bar stool.

Durability. Glass has a Mohs Hardness of 6.6 Scratching, chipping are not an issue if using round over tops (vs a 45 bevel which has 2 sharp edges). Repairs in field are possible. Scratches can be buffed out. The beauty of our heat strengthened textured glass is that scratches are rarely visible due to the textures below. You will notice far more scratches on a flat glass piece than on textured glass.

Installation. Textured Glass Countertop installations are not for for amateurs. Please make sure that your installers are THE BEST you can find.

Most Often Purchased For: Modern, Contemporary, Transitional, Coastal, Indoor, Outdoor, Kitchen, Bath, Backsplashes, Tables, Stair Steps, Glass Shower Walls.

Summary. Textured glass countertops are are a hygienic and luxurious material that add an artistic element to your kitchen, bath, table or restaurant. They come alive in the evening with thoughtful lighting and can truly appear to float. Our favorite countertop combination is a Textured Glass High Bar with LED and ceiling spot lights over a White Glass countertop. It’s a top dollar splurge, but if placed in high-value areas it can pay you back every day with a WOW! Factor and a high resale value for your home.

Glass Bar Top in Acqua Cafe Restaurant West Palm Beach

White Glass Countertops (Nanoglass) Prices and Buying Guide

Cost. The average retail cost of a White Glass countertop is between $125/psf and $250/psf.

Color. It is the purest white countertop available. See our comparison of white countertop options.

How is it Made. White glass countertops are a fusion of glass and silica at 2700 degrees, poured into forms, cooled, polished to a gloss finish. It is as non-porous as glass.

Largest Size. Slab sizes are 561” x 120” x 1.125” Maximizing the yield per slab lowers the cost.

Typical Thickness. 1.125” thick is the standard white glass countertop thickness. Lamination of edges can provide thicker edges. 1.125” thick white glass weighs 23lbs per square foot.

Design Options. White glass countertops can be fabricated into many shapes. Arced shapes vs Linear shapes take longer to polish and will add to cost. Water jetting glass usually runs about $150 per hour. The unbelievable strength of white glass allows you to create designs with MUCH wider cantilevers, and overhangs, without bracing.

Edge. Polishing White Glass takes many steps and a great amount of skill and effort. Make sure you inspect the quality of polish before signing a contract. Square polished edge with a roundover is standard.

Cutouts. Waterjet cutting sinks and faucets is recommended.

Lighting. White Glass is opaque and cannot be underlit.

Durability. White Glass has a Mohs Hardness of 7.0 Scratching, chipping are not an issue when using roundover tops. Repairs in field are possible. It is non-porous and you do NOT need to use sealers.

Staining. White Glass Countertops are by far the whitest, strongest, most stain-proof, UV-proof, cigarette and hot pan-proof, hair dye-proof, solvent-proof acid-proof material we have ever tested. For outdoor kitchens, it is the perfect material because it is 100% inorganic…and unlike quartz, whose plastic resin binder will yellow in the outdoor light. It also stays very cool to the touch (96 degrees on a 93 degree day) in direct Florida sunlight…amazing!

Installation. White Glass Countertop installations are performed with care, and is not for for amateurs. Pure white is the hardest to match seam color. We offer custom colored seam kits for our customers Please make sure that your installers are THE BEST you can find.

Often Used For: Modern, Contemporary, Transitional, Coastal, Indoor, Outdoor, Kitchen, Bath, Tables. Used in place of quartz countertops outdoors.

Summary. White Glass Countertops are a pure white, non-porous, hygienic and luxurious material. They make the apparent size of each room they inhabit appear 25% larger. In an era where we purchase countertops and homes by the square foot, adding 25% to the visual volume of your home adds tremendous value.They are also a very contemporary and modern countertop option that is great for outdoor countertops. When combined with stone or reclaimed wood paneling, white glass gives a very pure and interesting Jetsons-Flintstones juxtaposition.

White Glass outdoor Countertop Bar with waterfall edge at American Social restaurant in Tampa Fl

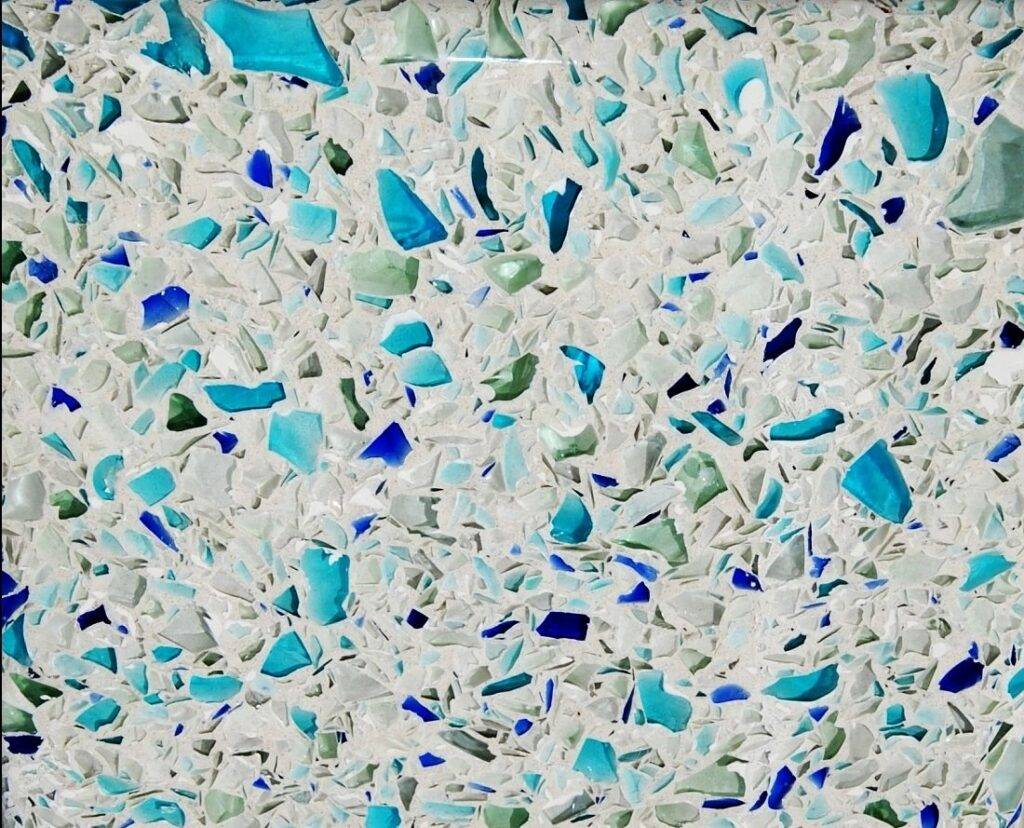

Sea Glass Concrete Countertops (Terrazzo) Prices and Buying Guide

Cost. The average retail cost of a Sea Glass Countertop is between $200/psf and $300/psf.

How is it Made. Sea Glass countertops are created from sand, aggregates, cement, fibers. Poured into custom forms, cured, and then polished to the matte or gloss finish. Sea Glass Countertops and Terrazzo countertops are ground to reveal aggregates. Concrete needs to be sealed as it is porous.

Sea Glass Countertop

Largest Size. Sea Glass countertops can be fabricated to lengths in excess of 12’. Expect to pay a premium when big pieces over 300lbs are installed. 1.5” concrete countertops weigh 20lbs per square foot which is about the same as granite.

Typical Thickness. 1.5” thick is the standard minimum concrete countertop thickness but 2” thick concrete is the most popular. Any thickness can be specified without lamination resulting in a beautiful one-piece look.

Design Options. Any shape can be created with a skillful fabricator.

Polishing. Polishing sea glass concrete to a matte finish is a multi-step process. Gloss concrete requires more effort. Matte concrete feels like a worn shell, and is very comfortable to touch. 90% of orders are matte.

Cutouts. Cutouts for holes, sinks can be moulded into the concrete or cut with standard diamond tools.

Color. The base color of white concrete is similar to canvas. Pigments can be added to the concrete mix to match any color. Expect to pay more for expensive pigments, and color matching services.

Terrazzo. Terrazzo is a matrix of concrete, pigments and aggregates. Aggregates can be recycled sea glass, SeaShells, Mother-of-Pearl, Agates, etc. “Vetrazzo” is a prefab slab with a high recycled glass content. All terrazzo needs to be sealed periodically just like concrete.

Lighting. Concrete is opaque. However, clever mating of concrete with glass and fiber optics can create very interesting effects.

Sealer. Sealing concrete is a must. Many topical “plastic” sealers are available, but they will yellow and/or peel over time. Plastic sealers hide the very popular tactile nature of concrete with a barrier. Penetrating sealers do an excellent job of preventing stains except from long-term food acid spills. They do not yellow, and leave the surface feeling soft and natural. Make sure you inspect the sealer quality before buying.

Durability. Sea Glass Concrete has a Mohs Hardness of 5.5 Scratching, chipping is not an issue if using round over edges. Repairs in the field are possible. Concrete requires attention to prevent long-term exposure to food acids which can etch the concrete. Concrete stains from organic sources can be removed with bleach.It is a 100% inorganic material it works well outdoor unlike quartz, whose plastic resin binder will yellow outdoors. Lighter concrete colors stay reasonably cool to the touch. It requires sealing every 3-5 years (wipe on wipe off) and can be refinished in the field.

Often Used For: Modern, Contemporary, Transitional, Traditional, Coastal, Indoor, Outdoor, Kitchen, Bath, Tables, Stair steps, Floors, Sinks.

Summary. Sea Glass Countertops are a luxurious surface and can be created in exactly any color and thickness you desire. Aggregates (such as shells and sea glass) included in the concrete allow for an unlimited artistic palette. They also make excellent sinks for bathrooms as they can be formed in a variety of creative designs. Concrete sinks with glass basins make for unusual, contemporary designs. Concrete can patina over time but this adds character to their perfectly imperfect nature. Concrete is a very historic material and plays well with glossy contemporary cabinets to give a very interesting “Jetsons-Flintstones” juxtaposition.

Concrete Countertops with Glass Bar