Last updated on February 11th, 2026 at 01:34 pm

Questions to ask Before Buying Glass Countertops in 2026

-

Interviewing Your Glass Countertops Fabricator

-

Author Qualifications

-

Glass Countertops Types and Terms

-

Textures for Glass Countertops

-

Cutting and Polishing Glass Countertops

-

Lighting Glass Countertops

-

Metal Support Brackets and Installation Techniques

-

Glass Countertops Cost

-

Installation and Shipping Glass Countertops

-

Remodeling Trends

-

Conclusion

-

ERRATA: The Dumbest Glass Countertop Ideas on the Internet

Custom Glass countertops are a hot design trends in Kitchen and Bath remodeling today. No other material enhances the visual beauty of your space like the translucent nature of glass and offers endless creative possibilities as a luminous focal point. This buyers guide will help you understand the many options available to make it “POP” in your home.

As a buyer, we recommend you ask lots of questions of your glass fabricator after website visits followed by On-Site tours and first-hand inspection of product quality.

Do your reputation research. Know what you are getting for your money in writing upfront. Here are some good interview questions to start…

Questions for your Glass Countertop Fabricator

Q: Where are your products Made… In the USA?

A: Downing Designs glass is made in Tampa, Florida in our kilns. NO tariffs here.

Q: Who will Measure, Design, Fabricate and Install? Are you trustworthy?

A: Experience matters. Jeff Downing will template, design, fabricate and he and his team will install in Florida. Jeff has 25 years experience in this business. As you can tell from his 5-Star reviews on Houzz , clients are genuinely happy with his responsiveness, and superior quality.

Q: Are client Designs inputs taken when designing Glass textures? Or do you just offer stamped molds?

A: Each Downing Design glass counter is hand-made to order. NOT a replica. We enjoy client ideas and incorporate them into the final glass product. Why pay a lot for a replica? You deserve an original texture that flows with your space.

Q: Does your Fabricator have high-quality photos on their website?

A: Downing Designs has hundreds for project photos on their Gallery.

Q: Is your Fabricator Passionate about excellence in the final installation? Or are they just a prefab slab exporter?

A: Just call. You will know in less than a minute about my passion for this art. We will give you written Quote with all options itemized and with Installation included.

Author Qualifications

This guide was written by Jeff Downing of Downing Designs, a professional design studio that has installed millions of dollars of custom Glass surfaces. He has an intimate understanding of glass countertop fabrication and is indeed very passionate about his craft.

Downing Designs has a truly unique approach where human interaction and creative insight are fluidly aligned to imagine a brighter future for your space. Great things happen (e g. Prototypes) when we cross-pollinate our ideas with others. The result is a functional piece of glass art that has an emotional connection with their clients.

If you Google “Buy Glass Countertops” you will see many keyword-stuffed, ad-driven sites posting misleading statements and very odd glass high bar support ideas. Please enjoy our ERRATA section at the end where we’ve called them out for their misleading statements and expensive glass countertops installed in strange, half-baked ways. Buyer Beware!

Glass Types and Terms

Glass Countertops can be fabricated from a variety of glass. Float Glass is commonly used. Float glass is a flat sheet created by “floating” raw molten glass (a mix of raw material and recycled glass cullet) over a bath of molten tin.

Float Glass glass pieces up to 177” x 127” x ¾” thickness are available and are well suited for flat, back painted countertops and splashbacks.

3/4″ Low iron Glass Backpainted White

Low-Iron Glass is a Float glass with low amounts of iron which render a light bluish hue. This is critical when viewing the edge, as you will see the color intensity greatly magnified. Low-iron glass is well suited for countertops and backsplashes.

“Clear” Glass is a Float glass with higher iron content that renders it a greenish hue. The thicker the glass, the deeper the hue. Dont use “Clear” glass if you are back painting the glass as it will tint your final result.

Fused Textured Glass is a process where sheets of float glass are thermoformed over a large ceramic sand bed or mould and fused at ~1450 degrees F, then annealed. The annealing process “heat-strengthens” the fused glass product to almost 2x annealed glass strength. Fused textured glass at 1.5” thick is very strong and is an extremely durable material that can be cantilevered to a much greater degree than most surfacing materials. Thicker glass e..g 2″ and 2.5″ is possible but the annealling times are longer and hence cost more.

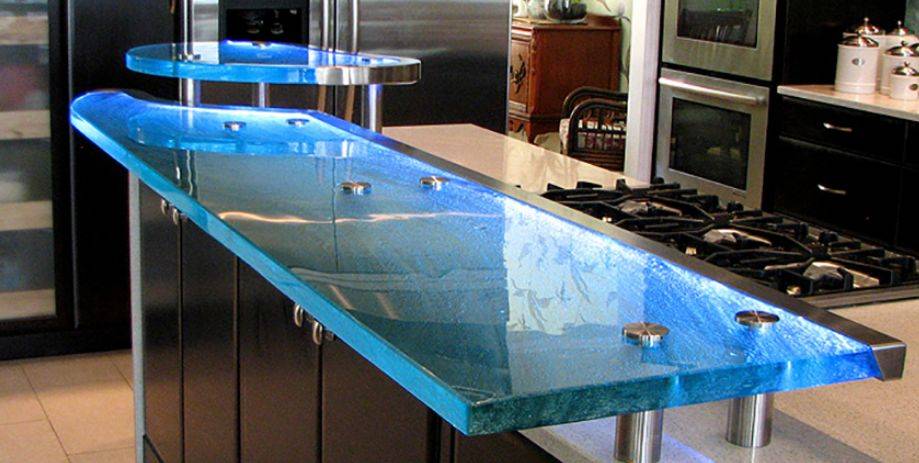

Glass Countertop Cantilevered 37″ from left Support

Textures for Glass Countertops

Texturing Glass Upon selection of the glass countertop to be used, fabrication can begin after measuring, templating, and texture design. A like a bespoke tailor, a full-service glass countertop designer-fabricator will demonstrate ALL of your options to accessorize your glass countertop to achieve the utmost in “wow” factor. These critical points include:

Stamped Textures provide a consistent textured look that is omni-directional. These can be interesting when selected for the right environment.

Hand Sculpted Textures are artistically carved into the kiln bed to create the texture you desire. Deep textures create drama and are spectacular when lit with LEDs and downlights. See our Fox News video showing some of this sculpting process.

- Designer Tip: Communicate and review pattern suggestions, and refine these until happy. Select a glass texture that enhances the personality of your room “flow”. Don’t settle for a stamped textured piece of glass when for the same amount of money you can have a custom designed statement piece that flows elegantly with the lines in your home. Make sure your texture flows from one piece of glass to another across the seam in multi-sectional countertops. See Video below for a glass counter that flows well with the room.

Hand Texturing Kiln Bed for Glass Countertops

Glass Cutting and Polishing

Kiln-formed glass must be cut to size and have holes drilled. Waterjets, wet saws and polishing tools with plenty of water are used. Make sure your glass fabricator has these in his shop to efficiently move your glass from kiln to cutting to polishing. Only the highest polish should be ordered. You will see poor polishing up close and personal. Make sure you inspect the quality of the edge polish in your sample. If it is anything less than optically clear, reject it! Your edge should offer a perfectly polished lens. It should look like your reading glasses…perfect,

- Also, 45 degree bevels present (2) sharp edges where the top meets the face. Gently rounded over edges are much more comfortable, and much less prone to chipping. See below picture illustrating those points.

Lines on Face due to Worn Out CNC bit…”Shiney but Liney”

Lighting Glass

Make sure you have a thorough Lighting plan for LED Edge Lighting, Down lighting and Ambient Lighting so they can all contribute to the WOW factor of your glass countertop.

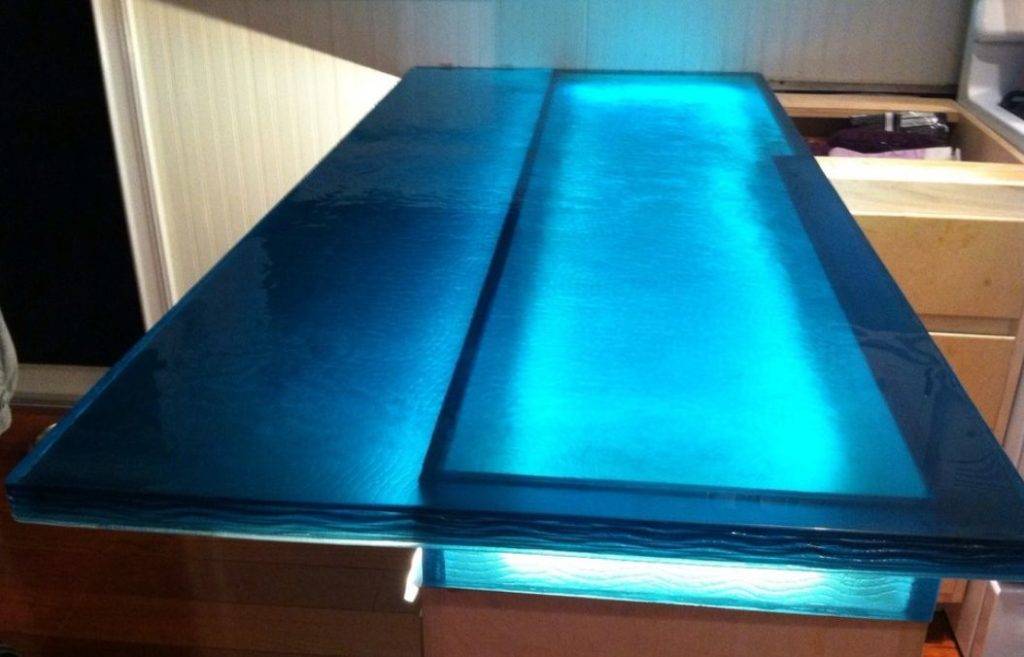

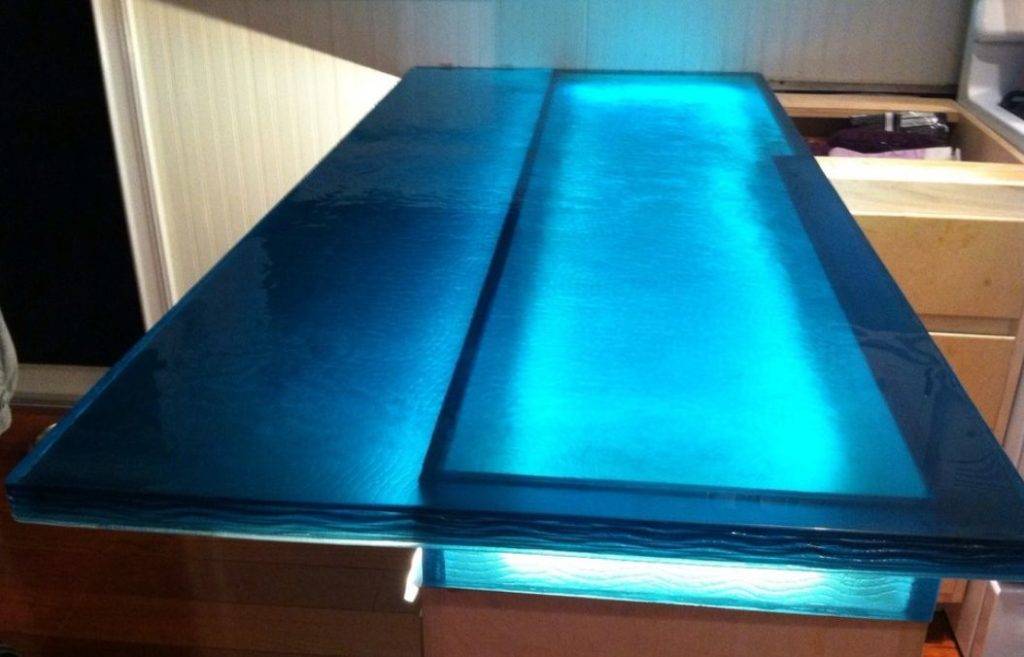

LED Edge and Down lighted Glass Countertop…Note Dramatic Shadows on Floor

LED Edge Lighting is typically this is the best way to light textured glass countertops. Narrow LED strip lights on the edge of the countertop allow for high levels of striking high-contrast color. Done right, your glass countertop will “POP”…especially at night. Color and brightness are achieved with a controller, usually a smart phone app. This produces millions of stunning colors that can even dance to your music. You will need to run wires from the LED strips to a controller and transformer to a 110v power outlet. Use quality LEDs…this is not a place to save money as they can be tricky to replace once installed.

- Designer Tip: Your LED cover and wiring should be minimalist and allow viewing into glass as well as reduce the pixel appearance from the front. Get a plan to conceal the LED wires through the supports and lower surface.

Minimalist LED Cover…no Visible Wires.

On A Lighter Side Note: Our “proprietary” research shows that properly lit Glass High Bars are in fact “Time Machines”. Apparently, a huge benefit of the upward angling and soft mood lighting from our glass high bars is that it “turns back the clock a few years”. (It makes my vintage 1959 wrinkles almost go away…we are not sure how to price that benefit just yet).

Down lighting from the ceiling will create a powerful mimic shadow upon the floor and lower surface. It is a perfect lighting technique for High bars to complement LED edge lighting.

- Designer Tip: Modern LED downlights are available that create a tight, well-defined X-Ray shadow upon the floor. They are powerful, dimmable and consume very little electricity. Aim the light to project the shadows where you desire…preferably at an angle to make the shadows look bigger.

Ambient lighting allows the glass to pop naturally during the day in a sunny location. Low iron glass is naturally beautiful when lit with sunlight. See the pictures and video below.

Glass Countertop without LED in Daylight

Same Countertop Down lit at Night

Under lighting Glass requires a tall structure on the underside of the textured glass to allow for even distribution of light…which may be unsuitably high for your countertop.

- Designer Note: It also creates a very “flat” lighting effect that minimizes the contrast of shadow vs light and robs textures of their visual depth. It “highlights” the rib structure of the underlying panels…and is not pretty. (see below). This technique does however work well with onyx slabs.

Underlit Glass Countertop…Looks like an XRay!

Glass Countertops Installation

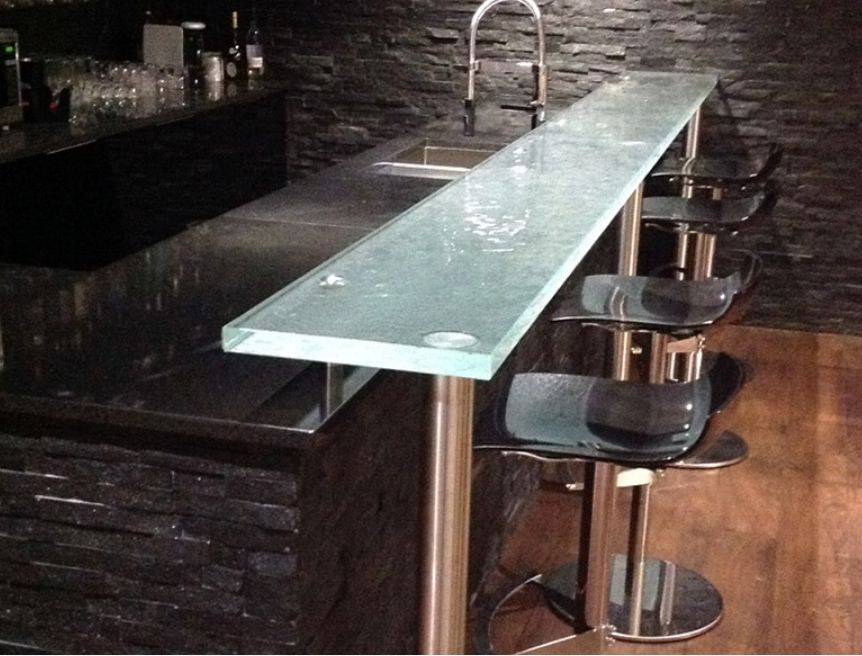

Supports Metal support brackets of all shapes and sizes are available. Custom metal supports must often be fabricated to suit unusual installs e.g floor-mounted supports. Your metal fabricator should be able to offer you any custom design you wish…not just some one-size-fits-all support. Make sure your plan for your high bar is sturdy and elegant. Methods of attachment of the glass to the support include:

- Silicone. Best used to attach textured glass to flat supports.

- Metal Caps. Low Profile caps are best if caps are used.

- UV glue. Fastest bond for flat glass to flat metal supports.

High Bar with (3) Low Profile Caps, No supports

High Bar with Low Profile Caps, Stainless Supports in Ground.

High Bar with Custom Supports…attached by Silicone

- Designer tip: Many designs are lazy and use ill-conceived support techniques. They often prevent you from freely rotating in your high bars stools because your knee hits the support. Or, they use “hockey puck caps” on top of the glass to prevent you from having an uninterrupted smooth flow across your high bar surface. Look for these “beauties” in the “Errata” section at the end of this article. Make sure your supports do not interact with your knees at your glass high bar. Look closely at the pictures above and below. They have a clean look owing to thoughtfully designed custom cantilevering brackets . They are concave on the high bar chairs side, thus making it very hard to hit your knee as you rotate your high bar chair.

Custom Bracket designed to Not Hit Your Knee

Back painting glass maximizes the visual depth of the textured glass countertop, backsplash or sink basin, while hiding the ability to see under or behind the glass.

Installation and Shipping of glass countertops.

Expensive Glass requires skillful planning and experienced manpower to install.

- Designer Note: We have been on a few time critical installations where cabinets, plumbing, electrical work, ceiling plastering were all being dome in the same kitchen at the same time! This is not good.

Please have a schedule that allows the glass counter to be one of the last installations...just like a valuable piece of wall art. Having too many tradesman in the room after installation increases the risk of damage to your artistic piece.

Crating for Shipping. Crates are specially fabricated for glass countertops with plenty of sturdy foam to cushion it during shipping. Make sure you purchase insurance t cover the cost of both the glass as well as the shipping costs.

Solid Crate for Shipping Glass Counters

Glass Countertops Cost:

Glass costs are listed below;

- $100+/sq. ft. for 1/2″ flat low-iron glass. Backpaint, thermoforming, waterjetting custom shapes, holes, etc. adds to cost.

- $350+/sq. ft. for 1.5” textured low-iron glass. LEDs, backpaint, custom shapes, size of piece, supports, installation, etc. add to cost.

- Delivery costs out of state add to the above.

Glass Countertops Remodel Trends

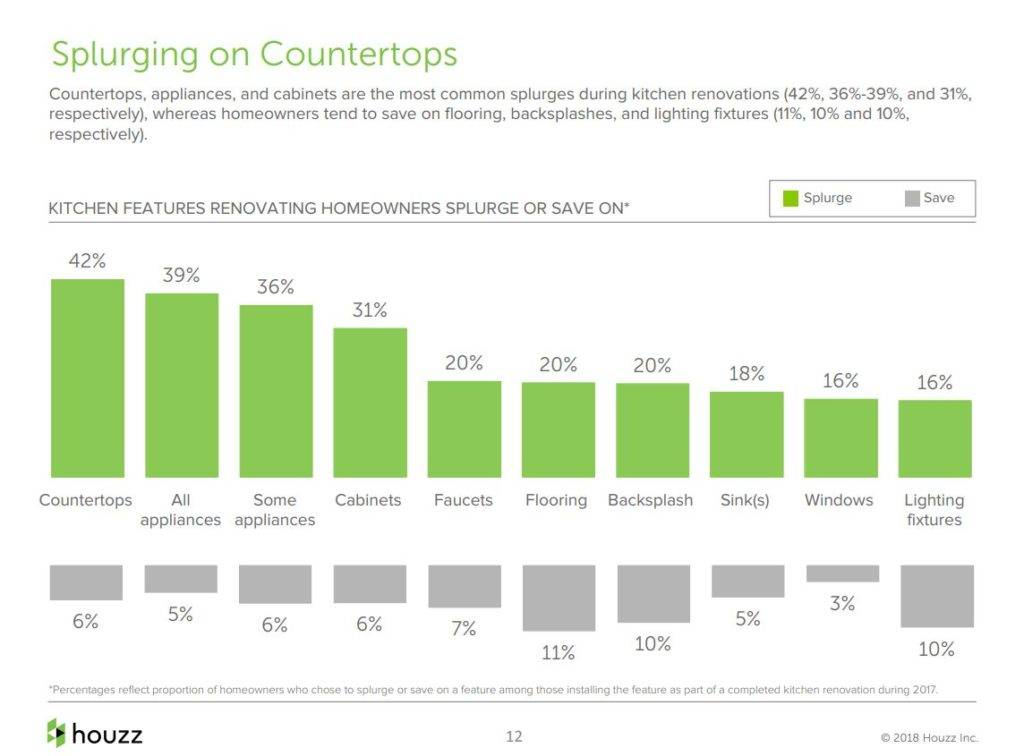

In an interesting article on Houzz, they show that homeowners are increasing their spending more on High-End countertops vs other kitchen elements.

Houzz Survey…Buyers are Splurging on Countertops

Conclusion

You are going to have to place your trust and money in someone to fully execute your glass countertop project. If your vendor cannot confidently lead you through each step in the design, template, custom textural sculpting, fabrication, lighting, back-painting, supporting, securing, shipping as well as installing, then find one who can …or…risk a poor outcome. Glass counters cost too much to risk a poor outcome in the hands of amateurs.

Find a passionate glass fabricator that can listen to you and bring out the best in your ideas, create a plan and lead you through the process. The result will be an unbelievable artistic “wow” piece in your home for many years.

Jeff Downing is the founder of Downing Designs in Downtown Tampa, FL. He has represented Hewlett-Packard and Philips Medical amongst others before quitting to open his custom design studio. His teachings and blogs help architects, designers, etc. to embrace creative new ways to use glass in their projects. He previously represented ThinkGlass for several years before purchasing his own kilns to bring his unique artistic glass visions to life.

ERRATA

STRANGE Glass statements we have scraped from the Internet…”Fake News”

“On average, the minimum cost for glass countertops per square foot is $75, while the maximum cost per square foot is around $105.”

Clearly they have never made a thick textured glass countertop.

“Annealed Glass—Similar to tempered glass, annealed glass has chemicals added to the resin mixture to increase its strength.”

A chemical added to the resin??? This is glass, NOT plastic.

“Nonetheless, there are many other factors that can increase or decrease the total cost of glass counters. Supplies such as sealants and adhesives add an average of $2.45 per finished square foot of surface area.”

Sealants???? Why do you need to seal glass? Its non-porous.

“Contact with acidic foods, drinks, and certain cleaners can affect the surface and require fixing”

Not unless you are serving hydrofluoric acid to your guests! Nonsense!

Odd Designs Ideas for High Bars

Underlit Glass Countertop…Looks like an XRay!

This ugly under lighting completely ruins an otherwise nice glass countertop. Very Odd looking.

Glass Countertop with Hockey Pucks and Archaic supports. Where am I supposed to sit ? Knee and Shin bashing will occur. Careful of those Hockey Pucks! Thanks, but I think I’ll stand…

Again, where am I supposed to sit? Knee bashing will occur. Shins are safe here. Robs the ability to seat people normally.

Posts to Floor Reduce Usable Bar Space

Glass Countertop with fat supports and LED covers

Where does my glass of wine and dinner plate sit? Look out for those hockey pucks! You cannot see the edge of the glass while cooking! Glass Counters should look great from all sides.

What is the Point? No Cantilever, Lots of Hockey Pucks,No room to clean under.

This client went with a slab vendor (Thinkglass) that merely took their money with no thoughtful advice (e.g. backpaint) to prevent this half-baked result. The result is a glass countertop that shows everything inside the cabinet. Thinking about themselves and not about getting this piece right!

Glass Countertop without BackPaint…NOT Pretty to see insides of cabinets

Jeff Downing

Founder, Lead Designer & Custom Glass Countertop Expert

Jeff Downing of Downing Designs, is a Tampa Florida–based design studio specializing in custom Glass Countertops, Glass Bar Tops, Glass Vanity tops and Glass Stair Treads. With decades of hands-on experience, Jeff is widely recognized for delivering textured glass surfaces integrated with LED lighting to create dazzling abstract statement pieces.

"Glass. Lights. Ambiance".